Grinding & Assembly (tool making)

The core of our business since 1969

Our highly-skilled team have a wealth of knowledge and experience as press toolmakers, gathering all machined parts for assembly and seeing through the entire process.

Working to fully detailed and dimensioned drawings our toolmakers complete the tool build ready for first press trial, through component inspection, tool completion, signoff and on site support.

Using our in-house try-out presses, we can build and trial tools up to 400 tonne with a maximum die set size of 2.75m x 1.5m. We also utilise a Stanko 160 ton press with a bed size of 1.25 x 1.7m.

Our Tooling Specialities

From concept to design and manufacture, Paragon Toolmaking is a one-stop shop for all your tooling requirements.

All parts inspected for tolerances and performance

Our team ensures the tools we manufacture produce parts which meet exacting level of tolerances and performance.

Each part is taken to our inspection department where it is checked and verified to the component drawing, with any further required adjustments then made to the producing tool.

How we work

With more than 50 years’ experience to call upon, we’re proud to have fine-tuned our tool-making process.

1

Concept Analysis

Every successful project starts with a clear brief. Once it’s fully understood by our toolmaking experts, we analyse the form and function. From this we develop the initial tooling concept ready to allow us to address every critical feature.

2

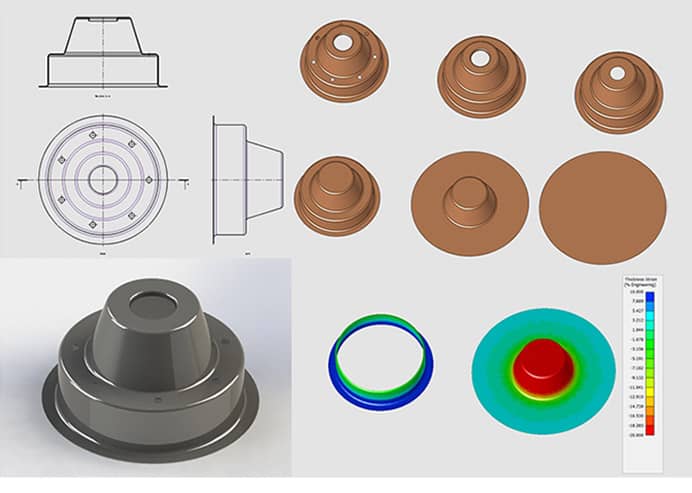

Design & Modelling

After agreeing any adjustments or modifications, we begin to create the final approved working 3D design – detailing every feature required to efficiently and confidently enter the manufacturing process.

3

Assembly & Production

Using the latest 3D manufacturing techniques we produce the high accuracy components required. Following accurate assembly the tools tested to ensure the required specification is achieved.

Can we make the tool you need? Send your design and find out

Got a rough pencil sketch, CAD drawing or CAD model of the product you require? We can evaluate its form, fit and function and help you decide on how to make it!

Dont just take our word for it

What our clients are saying

…Paragon always go the extra mile and ensure that everything is working perfect every time…

James Welbeck – Food company

The die ran extremely well at 50 parts per minute with good quality. We have now commissioned the tool ready for production. The toolmakers deserve a pat on the back.

Paul, New Tooling Engineer – Automotive – Sunderland

Our customer has laid down three sets of tooling, one in Taiwan, one in the UK and one with Paragon Toolmaking. The parts off the Paragon tool are the best by far.

Chris, – General Manager – Computer Casing Components – Tewkesbury

We’ve used Paragon Toolmaking for many years as we know they’ll provide the exact tooling we need, of the highest standard and longevity, and they are always there to offer help and support.

Keith – Process Engineer- White Goods – Rotherham

Latest News

Paragon Toolmaking

321 National Avenue

Kingston upon Hull

HU5 4JB

United Kingdom

Contact

Company Registration Number: 7567189

VAT Registration Number: 108775201