News

Embracing the Future of Toolmaking with Stampack Software

At Paragon Tools, we are committed to maintaining our status as an industry leader in the UK toolmaking sector. This commitment drives our continuous efforts to adopt cutting-edge technologies that enhance our capabilities and service offerings.

Our latest advancement is integrating Stampack software into our operations, a significant step forward supported by the ‘Made Smarter’ manufacturing match funding program.

What is Stampack?

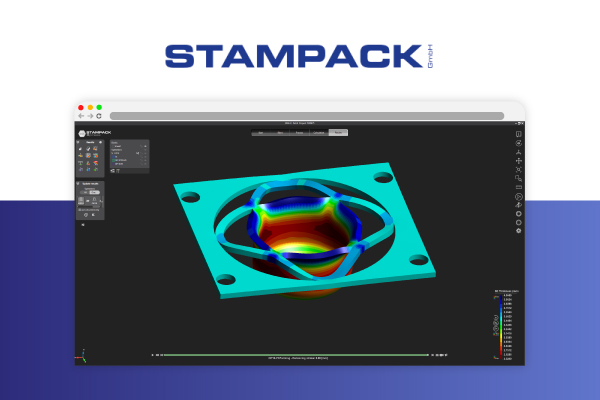

Stampack is a state-of-the-art simulation software specifically designed for the metal forming industry. At its core, Stampack allows us to create detailed, virtual models of our tooling solutions and simulate the metal forming processes before any physical manufacturing begins.

This means we can predict how a tool will perform, identify any potential issues in a digital environment, and resolve potential issues such as material wrinkling, tearing, or springback early in the design phase. This is faster and less costly than traditional physical testing.

Why Stampack at Paragon Tools?

Integrating Stampack into our workflow aligns with our strategic goals to enhance precision, reduce costs, and accelerate production times. The software’s ability to simulate complex tooling scenarios and predict outcomes such as material behaviour and surface defects ensures that we can perfect our tools before they even touch a piece of metal. This leads to fewer prototypes, less material waste, and a more streamlined development process.

Benefits for Our Customers

The adoption of Stampack software not only bolsters our capabilities but also translates into direct benefits for our customers:

- Enhanced Quality & Simulation Accuracy: With the ability to pre-test tools in a virtual environment, we ensure that the final product meets the high standards our customers expect, with reduced risk of defects.

- Reduced Prototype Costs: Stampack’s digital simulations allow us to significantly reduce the number of physical prototypes needed. This not only saves on material costs but also accelerates the development process, allowing us to make necessary adjustments virtually without the costly cycle of physical testing.

- Increased Productivity and Faster Turnaround Times: Stampack streamlines the design process, enabling quicker transitions from design to production. This efficiency reduces the time from concept to production, helping you get your products to market faster.

- Long-Term Savings and Improved Tool Longevity: Accurate simulations contribute to designing tools that undergo less wear and tear, enhancing their longevity and performance. This ensures consistent product quality and reduces the frequency of tool maintenance or replacement.

Get a Quote

Are you ready to experience the Paragon Tools difference with our advanced tooling solutions powered by Stampack? We invite you to submit a quote and upload any drawings you have. Let us show you how our cutting-edge capabilities can bring your projects to life with precision and efficiency.

Dont just take our word for it

What our clients are saying

…Paragon always go the extra mile and ensure that everything is working perfect every time…

James Welbeck – Food company

The die ran extremely well at 50 parts per minute with good quality. We have now commissioned the tool ready for production. The toolmakers deserve a pat on the back.

Paul, New Tooling Engineer – Automotive – Sunderland

Our customer has laid down three sets of tooling, one in Taiwan, one in the UK and one with Paragon Tools. The parts off the Paragon tool are the best by far.

Chris, – General Manager – Computer Casing Components – Tewkesbury

We’ve used Paragon Tools for many years as we know they’ll provide the exact tooling we need, of the highest standard and longevity, and they are always there to offer help and support.

Keith – Process Engineer- White Goods – Rotherham

Latest News

Paragon Tools

321 National Avenue

Kingston upon Hull

HU5 4JB

United Kingdom

Contact

Company Registration Number: 16843484