News

New £350,000 CNC milling machine extends capacity for large 3D forming projects

Paragon Toolmaking General Manager Kevin Batty says the business is better placed to handle larger and more specialist projects after adding new industry-leading machinery to the factory floor.

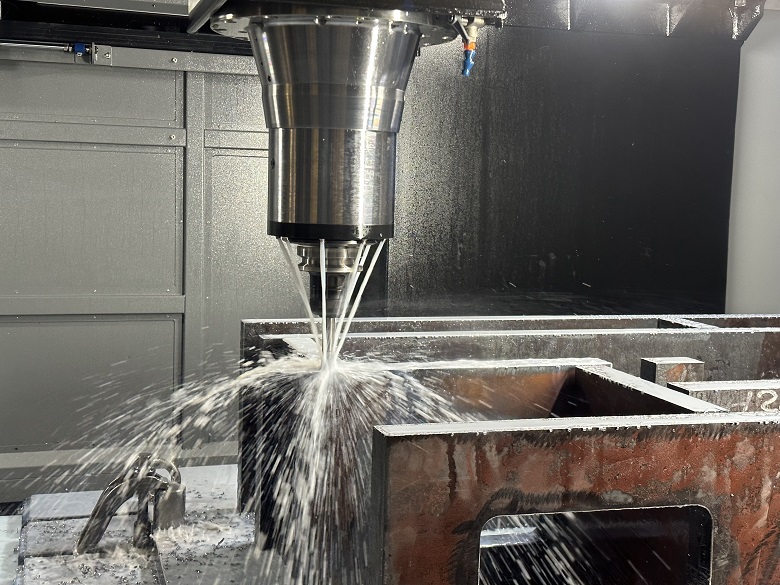

The business recently took delivery of a new Hurco DCX32i CNC (Computer Numerically Controlled) Milling machine – representing a £350,000 business investment into maintaining its reputation for having one of the UK’s best-equipped tool rooms.

With a 3m x 1,700 bed, it can cope with much larger plates and die sets than its predecessor, which has been one of Paragon’s most trusted pieces of machinery for more than three decades.

It will bring greater speed and efficiency, be able to handle much larger 3D forming projects, and those using more complex parts requiring greater intricate details.

“This is a significant investment for our business, but one which will bring immediate improvements to our abilities on the factory floor in terms of our capacity, capability and efficiency when working for customers,” he said.

“Perhaps most importantly, we will now be able to manufacture and form much larger 3D components, whereas in the past, when very large projects have come to us, we have had to create multiple parts and join them together.

“It also brings increased speed, better accuracy and improved cutting performance to our manufacturing process. Our old machine was a fantastic piece of kit and has served the business so well for 30 years, but due to its age, it took a significant amount of man time to operate and maintain, which is a cost to the business.

“This new machine is much more automated, and that will free up valuable time for our team to work on other jobs, improving the efficiency on our factory floor further.”

Paragon staff eager to see benefits

For CNC Machinists Josh McGowan and Andy Moat, the investment will make a huge impact on their daily jobs.

“The machine we are replacing was a superb piece of equipment but it took up quite of lot of time overseeing each and every process, and it would often be quite slow when working on complicated designs,” said Mr Moat.

“CAD technology has advanced so much in recent years, and that meant the old machine which we have replaced was sometimes struggling with the more complex designs,” added Mr McGowan.

“This machine is able to do the most intricate and complex jobs with ease, cutting down our production times. The feed and speeds are much quicker, it reads all the coordinates quicker, and they’ll also be much less hand-holding needed from us, and less maintenance required.”

Alongside the £350,000 investment into the new machinery, Paragon Toolmaking has also invested in a completely new tooling set to be used exclusively on the machine.

“It has been important to fully stock the machine with new tooling to ensure the very best level of performance,” said Mr Batty.

“We’re investing in ensuring the highest standard of UK manufacturing, and that is something we are proud of.”

Business investment is vital for continued success

Owner Daniel Beaumont said: “Continued investment in new equipment is crucial for Paragon Toolmaking to remain at the forefront of the industry.

“As technology and manufacturing processes evolve, it becomes essential for companies to adopt advanced equipment to enhance productivity, efficiency, and competitiveness by investing in state-of-the-art machinery,

“We can streamline operations, explore new design possibilities, reduce production times, develop innovative solutions, and expand our range of services to deliver higher-quality products to our customers.”

What does a CNC Milling Machine do?

A CNC milling machine is a computer-controlled cutting machine that shapes solid materials by removing material using rotary cutters. It is commonly used in manufacturing, aerospace, and automotive industries for its high precision and repeatability. CNC milling machines are perfect for creating complex shapes and producing intricate parts and components.

The CNC Milling Process

By securing the workpiece on a CNC milling machine, the cutting tool effortlessly shapes and cuts the material, allowing for high precision and repeatability. This versatile process enables the creation of various shapes, contours, and intricate designs. With the ability to change and program the cutting tool, CNC milling delivers exceptional precision and accuracy in producing complex parts, offering endless possibilities for custom-designed components.

Paragon Toolmaking

321 National Avenue

Kingston upon Hull

HU5 4JB

United Kingdom

Contact

Company Registration Number: 7567189

VAT Registration Number: 108775201